Hello! Sorry we’ve been so quiet. From the Itchen to Italy, it has been a busy year for REAPsystems. Keep reading to find out what we’ve been up to as well as exciting sponsorship opportunities.

Covering period Jan 2017-March 2018

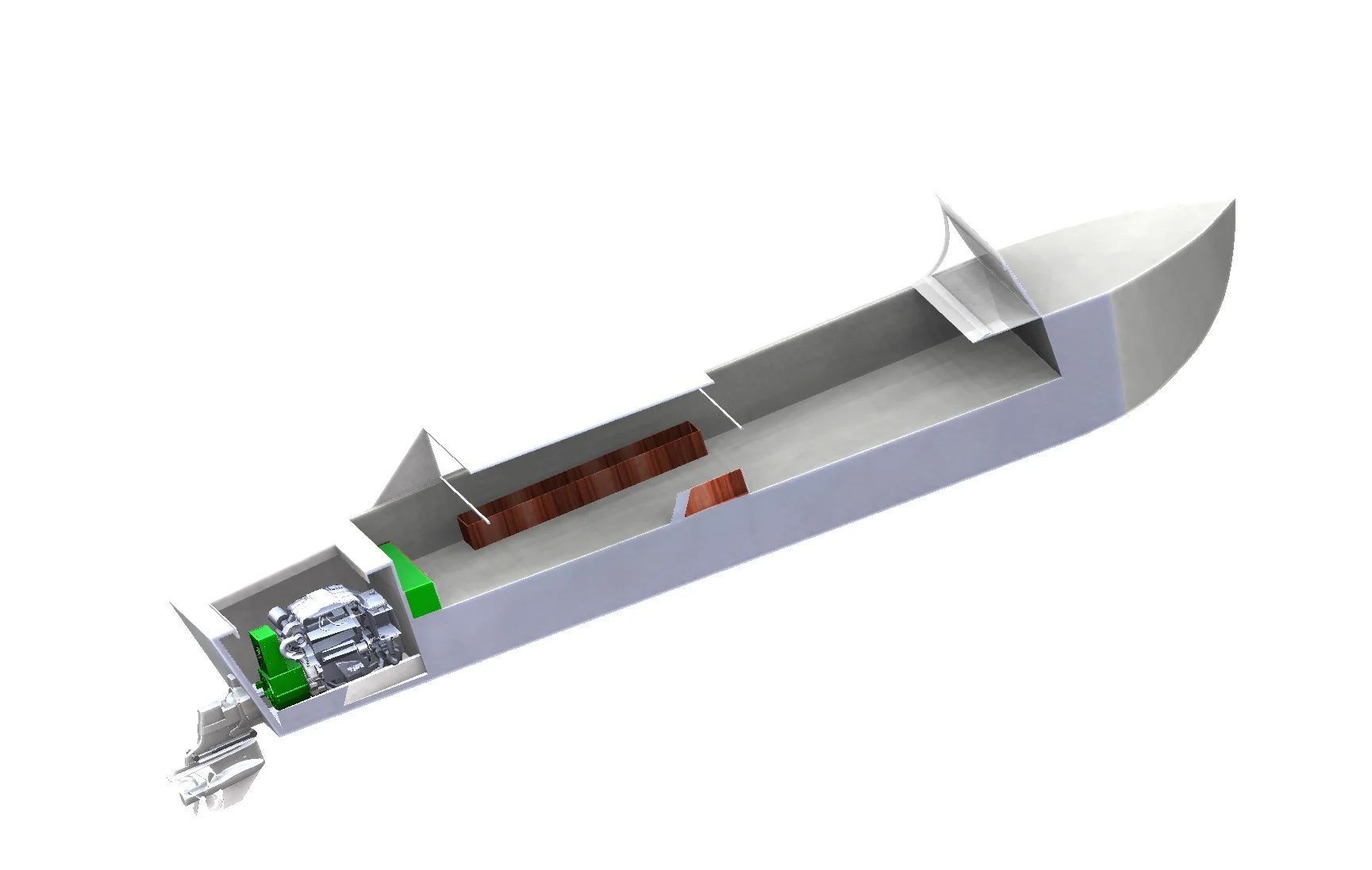

Visualisation of the Venice Hybrid Taxi Boat

New ideas: The Falmouth Ferry

January 2017 saw us take the first steps in expanding our Hybrid fleet; the new challenge is converting a ferry in Falmouth, Cornwall UK, to hybrid electric. By May 2017 Cornwall Ferries Ltd. had got on board with the idea (excuse the pun) and joined the Hybrid Electric Vessel Integrated Motor Assist (‘HEVIMA’) Project. They volunteered their flagship Kingsley II to be converted to hybrid. She was built in Cornwall by Percy Mitchell in the 1940s and after refurbishment will find a new lease of life trialling green, reliable transport along a new route on the Falmouth River.

The Kingsley II. The Park & Float ferries have covered over 95 000 miles between them!

The Kingsley II. She might look a little tired now but watch this space!

The Park & Float service has prevented 110,000 cars contributing to Falmouth's congestion and poor air quality during summer months, that’s more than 20 000 each year! This saves a huge 22 tonnes of carbon dioxide and 7 tonnes of carbon pollution. Installation of the REAPsystems drop-in hybrid engine will improve these figures even further, whilst also reducing noise, vibration and fuel consumption. During slower parts of the journey the ferry will run off electric. Crucially this will benefit areas around the busy coastal town and also upstream in important, environmentally sensitive, National Trust areas.

There are several partners involved in the HEVIMA Project. These include Cornwall Ferries Ltd. (CFL), Babcock, Mainstay Marine, Lloyds Register, University of Southampton, Marine Southeast (MSE) and REAPsystems. With support from Innovate UK- the UK’s innovation agency and Dstl.

Meet the HEVIMA Project team

Out and About: An overview of some of the events we attended last year

Riverfest, Southampton UK, in May provided an opportunity to demonstrate our electric rib to the 4000 locals in attendance. People of all ages enjoyed rides on the River Itchen, without the fumes and noise of diesel we could still enjoy the music coming from the bankside fun!

Locals enjoying the benefits of electric on the rib at Riverfest, Southampton, UK

Dennis was invited to present the HEVIMA Project and hybrid boat propulsion system technology at Seawork International in June 2017. Seawork International is Europe’s largest commercial marine exhibition so we were thrilled to have the opportunity to present our work and ethos to other influential professionals. The agenda last year was ‘Can I reduce my vessel operating costs?’. Dennis’s expertise in maximising efficiency through hybrid propulsion allowed industry leaders to consider alternative approaches to vessel optimisation.

Dennis presenting at Seawork International last June

Just a few days later we were at National Clean Air Day in Southampton, UK chatting about the importance of tackling air pollution. We took the electric rib and our little electric VW along to help raise awareness and give people the opportunity to see an electric vehicle and learn more about them. Air pollution is a serious problem which impacts all of our health; it increases the risk of getting lung cancer, contributing to 1 in 13 cases. Simple ways you can reduce the amount of air pollution you create include walking where possible, switching your engine off when stationary and choosing electric or hybrid options when upgrading your car (save yourself some ££ on road tax too!).

We enjoyed bringing out the old electric VW for Clean Air Day

One step closer to Venice – first Taxi Boat trials as a functioning hybrid!

By the end of June, the Venice Taxi Boat had its hybrid engine installed and fully functioning, it was time for trials! This was a really exciting day though unfortunately it turned out we needed to do a bit more tinkering! We didn’t let that perturb us as it’s all part of the process, but it was back to the workshop for now with more lessons to learn.

Our first fully hybrid trials - bottoms up, heads down as we try work out a few issues!

Throughout July and August we continued work trialling the Venice Taxi Boat, once we’d solved the final few problems we started demonstrations.

A glimpse behind the scenes - meet our glamourous team of engineers working out the final few complications!

What does this hybrid drop-in engine we’re always talking about actually look like? The green box on the left is the battery which powers the boat during slower parts of the journey, when a bit more speed is required the diesel engine on the right is used. This drop-in system is easily installed in a whole range of vessels, optimising their efficiency and eco-friendliness!

The boat was soon ready thanks to our fantastic team and she was very busy for the rest of the year with plenty of trips and demonstrations. Check out our travels on the photos below!

Brian and Dennis before popping over to the Isle of Wight on the hybrid Taxi Boat. Brian helps us out with driving the boat and is actually overseeing its transport to Venice later this year. Find out more about his services here www.boat-towing.co.uk

Navigating a few locks in Hythe and enjoying the beautiful sunset!

Out and about in Southampton again, making the most of summer!

We also went to the Southampton Boat Show, you could find us with our friends at Hyundai Seasall on their stand where we were giving out leaflets and chatting about our hybrid technology. We also got the chance to show off the Venice Taxi Boat when we picked up Sean Strevens, owner of Cheetah Marine, from the Isle of Wight to arrive in style at the show. He loved it!

In October we were at the Hilton Ageas Bowl Convention Centre in Southampton, UK displaying our Hybrid Venice Taxi Boat and the electric rib for The Big Green Event Expo. The Expo brings together hundreds of exhibits to help businesses improve environmental and facilities management and increase awareness of changing customer attitudes. Solent Journalism covered our attendance writing an article about Project Venice, the link is below if you’re interested!

www.solentjournalism.co.uk/eco-friendly-water-taxi-developed-in-southampton

Press coverage of the Hybrid Venice Taxi Boat at The Big Green Event in Southampton.

Demonstrations to our Italian friends from Venice!

The 20th September was an important day for us as we were demonstrating the Hybrid Venice Taxi Boat to our contacts in Venice. He might not have been too impressed with the weather here in Southampton, UK but that’s fine because he loved the boat! “This is the best hybrid system they have ever seen and tested - REAP must continue to develop and sell this system." We were so pleased by this response and now we have collaborated in developing plans to move the boat to Venice this summer. Once there it will be trialled as a fully operating taxi boat for a few months in the run up to PlugBoat 2018 and the Venice Film Festival. Please see our sponsorship link below if you’d be interested in making the most of this fantastic, unique advertising opportunity!

www.reapsystems.co.uk/sponsorkit

Certosa Island. Our taxi boat will provide transport between the island and nearby Venice, which can be seen in the background on the left.

Well, that’s a wrap on 2017! 2018 promises to be another dynamic and exciting year at REAPsystems with development of the next generation hybrid system already underway. This system will be installed aboard Kingsley II, parts for which are already starting to arrive!

Out with the old and in with the new! Kingsley II’s new Hyundai Seasall engine, not a bad swap we’d say!

The rest of the parts for the HEVIMA Project will continue to arrive over the coming months. The plan for now is an official launch event to show off the Kingsley II in all her restored glory in Falmouth, Cornwall UK this summer so keep an eye out for updates!

Beautiful Falmouth, Cornwall UK. Location of the Kingsley II launch for the HEVIMA Project later this year.

Further plans for the future involve updating the hybrid system and battery for the Venice Taxi Boat ready for more trials and demonstrations this summer in Southampton. Following those the boat will be shipped to Venice for more trials and demonstrations of the reliability of the drop-in hybrid system. Then, you’ll be able to find us showing off at the Venice Biennale and we’ll be shuttling participants for the next PlugBoat event (link below).

www.plugboat.com

We will also be at the NEXT GENERATION Marine Power & Propulsion Conference where Dennis has been invited to give a talk on designing and integrating diesel-battery-electric solutions for commercial craft. The event focuses on viable energy solutions for vessels of all sizes and is taking place as the Grand Harbour, Southampton, UK on 18-19th April 2018. If you’re interested in attending or you’d like more information, please see the link below.

hybridmarine-power.com/news-detail/next-generation-power-&-propulsion-2018/326/